Winston Sp600 Solution for High-speed Paper Cutting Machine in China

Abstract: In order to improve the equipment automation level and production efficiency of the tissue paper post-processing link of the paper cutting machine, reduce the production cost, and enhance the competitiveness of customer equipment in the terminal, under the general trend of domestic substitution imports, this article focuses on the application of Winston full set of industrial control products, through the process improvement of the paper cutting machine equipment machinery and the introduction of PLC control, servo and VFD technology, whether it is the production efficiency of the equipment, or the cost performance of the equipment, it has been greatly improved.

Keywords: post-processing, paper cutting machine, servo, VFD, Winston

1. Preface

The main links of the production line of tissue paper are composed of the following equipment: paper making machine, rewinding slitting machine, folding paper machine, paper cutting machine and packaging machine. Tissue paper is a fast-moving consumer product, and it can be roughly divided into drawing paper and coil paper according to the use. The demand is huge, so all kinds of tissue paper machinery and equipment also have a huge market capacity. Paper cutting machine is an important part of the tissue post-processing equipment. And it is also known as the large rotary paper cutting machine,whose main body is highly mechanized, automated equipment. Due to the limitations of the mechanical structure and speed regulation device, the old paper cutting machine has great limitations in terms of paper cutting specifications and production efficiency, and the after-sales maintenance of the equipment is very time-consuming and labor-consuming. Especially in the rapid development of industrial control today, the competition is particularly fierce, for OEM equipment manufacturers, equipment upgrading is particularly important, this article mainly introduces the application of Winston Sp600 system solutions on a paper cutting machine. The results prove that the production efficiency of the equipment has been greatly improved, the loss of raw materials has been greatly reduced, the mechanical process and automation level of the equipment has been greatly improved, and the maintenance of the equipment has become simple and easy to understand.

2. Introduction to the paper cutting machine system scheme

2.1 Paper cutting machine principle

The main job of the paper cutting machine is to fold the long strips of paper with different widths produced by the front road process equipment folding paper machine, cut them to a fixed length and then transfer them to the back packaging link through the conveyor belt, thus forming the square or round finished paper towels that we see every day. For a paper cutting machine to operate with high efficiency and precision, you need:

1, when the servo is running a fixed length, the position should be accurate and the response should be fast;

2, When the servo motor is started and stopped, the dynamic response to the drive is very high;

3, Single/dual channel transmission servo in the operation of the cutter encoder, the synchronization performance requirements are very high. Combined with the application needs of different occasions, the paper cutting mode summarized can be divided into: 1, the whole cutting mode: do not cut off the paper head and paper tail, cutting raw materials; 2, The head and tail mode: cut off the paper head and paper tail; 3, the head cutting mode: only cut off the paper head without cutting the paper tail; 4, the tail cutting mode: only cut off the paper tail without cutting the paper head.

In view of this, Winston launched the Sp600 system solution, including: Sp600-PLC+VS070-HMI+DA200 series high-performance servo (EtherCAT bus type) + GD350 series high-performance multi-function frequency converters.

2.2 Introduction to the Winston solution

2.2.1 Paper cutting machine solution features

1, Excellent control mode: most of the paper cutting machines on the market are using small PLC pulse control for position positioning, wiring is more cumbersome, low stability. The use of Winston Sp600 series medium-sized PLC and servo through the EtherCAT bus control, eliminating the need for more wiring of the electrical cabinet, the high-speed bus and motion control algorithm combined, to ensure the real-time operation, high responsiveness and stability.

2, Friendly human-machine interaction: VS series HMI is a human-machine interface with rich display, huge memory, powerful configuration and simple use. Human-computer interaction functions in all areas of industrial automation can be easily realized.

3, Electronic cam synchronization function: the dual-channel transmission axis servo follows the cutter encoder to take the electronic cam control, and the synchronization performance is good.

4, Other features: including: pneumatic sharpener, parameter control panel settings, to ensure the normal use of round knives; combined with the requirements of different customers, through HMI to choose to achieve a variety of paper cutting head or paper cutting tail needs.

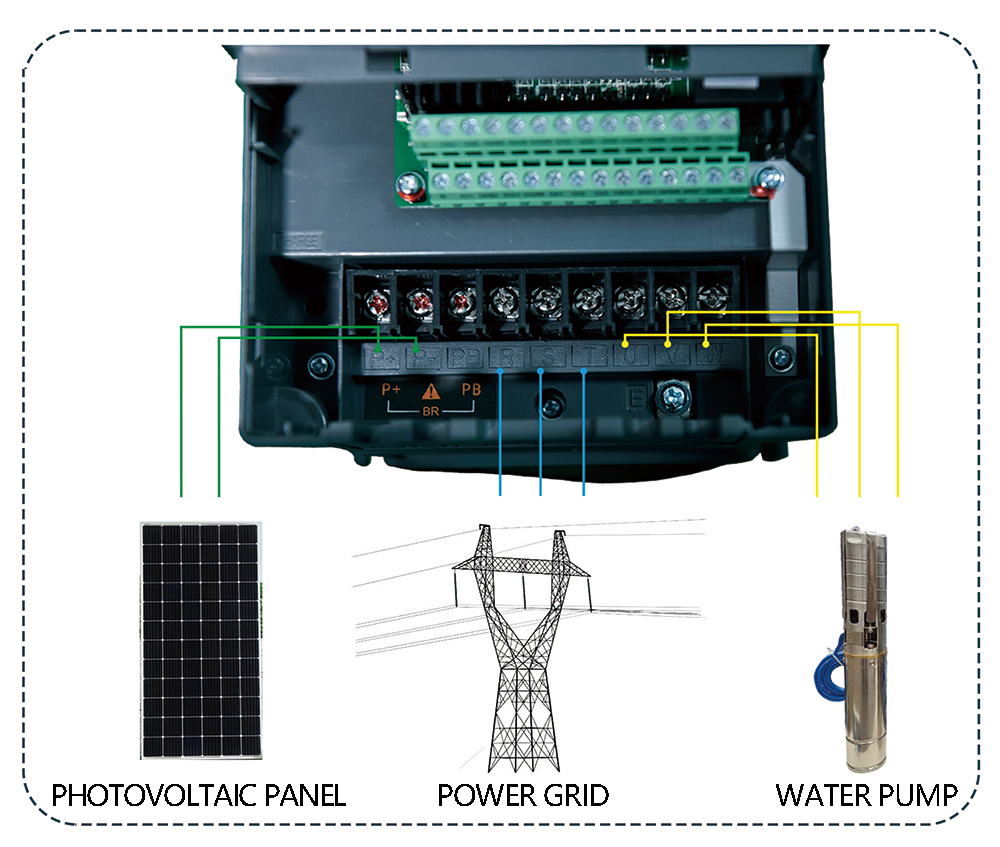

2.2.2 Paper cutting machine system diagram

3. Advantages of the paper cutting machine system solution

1, Flexible and adjustable paper cutting specifications: facial tissue specifications: L=90~250mm, W=60~150mm, H=60~120mm; coreless roll specifications: diameter D<=120mm, L=90~250mm, with automatic flattening function;

2, Improve the production efficiency of the whole machine: with the use of Sp600 motion controller and EtherCAT bus servo system and the use of electronic cam function to improve the synchronization effect, the maximum production speed of a single channel can reach 150 ~ 200 cuts/min, the maximum production speed of the dual channel can be up to 160 ~ 200 cuts/min, and it is easy and convenient to adjust when cutting face towels or rolls of different sizes. The paper clip can be adjusted at any time on different sizes of face towels, no need to replace different paper clips. The cutting surface is clean, flat, and will not squeeze or damage the face towel, thus greatly improving production efficiency.

3, After-sales maintenance: less wiring, easy troubleshooting. The program structure is simple, and the motion control function block omits a lot of calculation work for small PLC programming, which is convenient for customers to change and maintain.

4, Follow-up development: From the mechanical design and process link to participate in the development of new models, it puts forward improvement and optimization suggestions for customers to develop new models, such as the 3/4 channel paper cutting machine system that will be developed successively.

4. Customer value

1, Compared with the previous paper cutting method, the electronic cam synchronization method is adopted, that is, single/dual channel transmission servo follows the cutter encoder, and the length of the synchronization area can be arbitrarily set, so as to achieve any length of cutting, improve the degree of automation of the equipment.

2, The production efficiency of the whole machine of the equipment is greatly improved. Combined with different cutting specifications, the maximum production speed of a single channel can reach 150 ~ 200 cuts/min,and the maximum production speed of the double channel can reach 160 ~ 200 cuts/min. Compared with the old equipment, the efficiency is increased by at least 30%. In addition, when cutting different sizes of face towels or rolls of paper, the cutting length and paper cutting method are set through HMI, which is simple and convenient to adjust.

3, A full set of solutions using Winston brand to replace the previous foreign brands. And Winston can continue to provide customers with faster and better service and support.

4. Winston can provide customers with fast after-sales service support.

5. Application pictures

6. Ending

Winston Sp600 system solutions are used on paper cutting machine to fully meet customer requirements. The equipment is stable in operation, easy to maintain, low base paper loss rate, high production efficiency, and customers have mass-produced.

Related Products

SP600 series inverter